MotoGP replacement parts represent a fascinating intersection of cutting-edge technology and the relentless pursuit of speed. These components, meticulously engineered for peak performance, are crucial for maintaining competitiveness at the highest level of motorcycle racing. From carbon fiber bodywork to titanium exhaust systems, the world of MotoGP replacement parts offers a glimpse into the materials science and engineering innovations driving the sport forward.

Understanding the nuances of these parts is key to appreciating the intricate details and technological advancements that define MotoGP.

The demand for these high-quality components extends beyond the professional racing circuits. Enthusiasts and amateur racers alike seek out MotoGP replacement parts to enhance their own machines, benefiting from the trickle-down effect of technological innovation. This pursuit of performance improvements drives a thriving aftermarket, offering a wide range of options catering to diverse budgets and skill levels. The availability of these parts allows riders to customize their bikes and push the boundaries of performance, albeit within the limits of their skill and the track’s safety regulations.

The world of MotoGP is a thrilling spectacle of speed, precision, and cutting-edge technology. Behind the scenes, however, lies a complex network of maintenance and repair, heavily reliant on the availability and quality of replacement parts. This article delves into the intricacies of MotoGP replacement parts, exploring their types, sourcing, importance, and the technology behind their creation. We’ll cover everything from engine components to chassis parts, ensuring a comprehensive understanding for enthusiasts and professionals alike.

Understanding the Demand for MotoGP Replacement Parts

The demands placed on MotoGP machinery are unlike anything seen in other forms of motorsport. The bikes endure immense stress during races, pushing components to their absolute limits. This leads to a high rate of part wear and tear, necessitating a constant supply of high-quality replacements. The need for rapid turnaround times is also critical; a delayed repair can mean the difference between victory and defeat.

This high-pressure environment necessitates a sophisticated logistical system and a network of specialized suppliers.

Types of MotoGP Replacement Parts

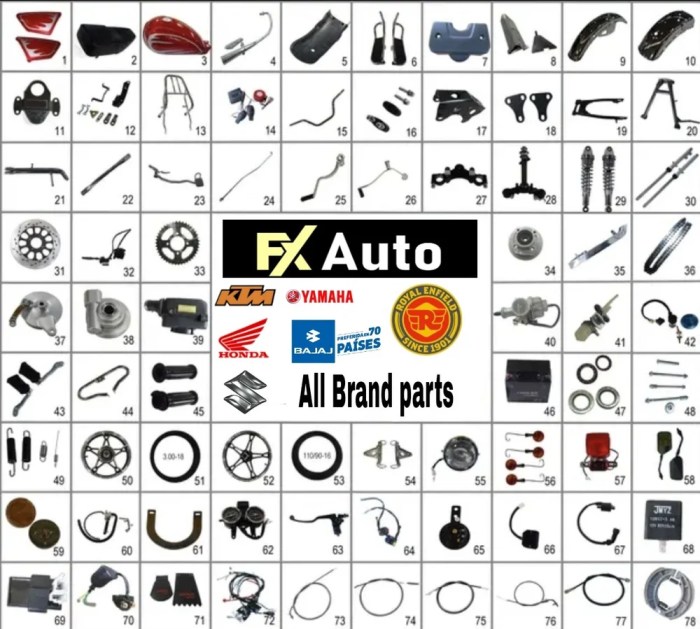

The range of replacement parts needed in MotoGP is vast and varied. They can be broadly categorized as follows:

- Engine Components: This includes crucial parts like pistons, connecting rods, crankshafts, cylinder heads, valves, camshafts, and various gaskets and seals. These components are often manufactured using exotic materials and advanced techniques to maximize performance and durability. The slightest imperfection can significantly impact engine performance and reliability.

- Chassis Components: The chassis, including the frame, swingarm, and forks, experiences significant stress during races. Replacement parts for these components are equally crucial, ensuring optimal handling and stability. Materials like carbon fiber and titanium are frequently used for their lightweight yet robust properties. Specific areas like the swingarm pivot and steering head require meticulous precision in manufacturing.

- Electronics and Sensors: Modern MotoGP bikes rely heavily on sophisticated electronics and sensor systems for data acquisition and control. Replacement parts for these systems, including ECU units, sensors, wiring harnesses, and actuators, are essential for maintaining optimal performance and safety. The reliability of these components is paramount, as any malfunction can have severe consequences.

- Brakes and Suspension: High-performance brakes and suspension systems are critical for safety and speed. Replacement parts for calipers, rotors, brake pads, forks, shock absorbers, and linkages are essential for maintaining consistent braking and handling characteristics. The materials used are often specialized, designed to withstand extreme temperatures and forces.

- Fairings and Bodywork: While not directly impacting performance in the same way as engine components, fairings and bodywork are crucial for aerodynamic efficiency. Replacement parts are needed to repair damage sustained during crashes or to accommodate changes in aerodynamic setup. These are often made from lightweight carbon fiber composites.

Sourcing MotoGP Replacement Parts

The sourcing of MotoGP replacement parts is a complex process involving specialized manufacturers, distributors, and the teams themselves. Many manufacturers work directly with the teams, providing bespoke parts tailored to their specific needs. The supply chain must be highly efficient to ensure rapid delivery of parts to the track. This often involves air freight and express delivery services to minimize downtime.

The Role of Technology in Manufacturing, MotoGP replacement parts

Advanced manufacturing techniques play a crucial role in producing high-performance MotoGP replacement parts. Techniques such as:

- CNC Machining: Used for creating highly precise components with intricate geometries.

- 3D Printing (Additive Manufacturing): Allows for rapid prototyping and the creation of complex shapes that would be difficult to produce using traditional methods. This is especially useful for creating customized parts.

- Forging and Casting: Used to create strong and lightweight components from various metals and alloys.

- Carbon Fiber Layup: Used for creating lightweight and strong bodywork and chassis components.

are employed to ensure the highest standards of quality and performance. The use of advanced materials like titanium alloys, carbon fiber composites, and ceramics is also commonplace, further enhancing the performance and durability of the parts.

The Importance of Quality Control

The quality of replacement parts is paramount in MotoGP. A faulty part can lead to catastrophic failure, potentially resulting in accidents and significant financial losses. Rigorous quality control measures are implemented throughout the entire manufacturing and supply chain. This includes:

- Material Testing: Ensuring that the materials used meet the required specifications.

- Dimensional Inspection: Verifying that the parts are manufactured to the correct dimensions and tolerances.

- Performance Testing: Evaluating the performance of the parts under simulated race conditions.

These processes ensure that only the highest quality parts are used in MotoGP machines.

Frequently Asked Questions (FAQ)

- Q: Where can I buy genuine MotoGP replacement parts? A: Genuine MotoGP parts are typically not available to the public. They are primarily sourced by the teams directly from manufacturers.

- Q: How much do MotoGP replacement parts cost? A: The cost varies greatly depending on the part and the materials used. Some components can cost thousands, even tens of thousands, of dollars.

- Q: What materials are commonly used in MotoGP replacement parts? A: Common materials include titanium alloys, carbon fiber composites, magnesium alloys, and high-strength steels.

- Q: How long does it take to replace a part during a race? A: This depends on the complexity of the repair. Simple replacements can be done in minutes, while more complex repairs can take much longer.

- Q: Are there aftermarket replacement parts for MotoGP bikes? A: While some aftermarket parts exist, they are generally not used in professional racing due to the stringent requirements for performance and reliability.

Conclusion

The world of MotoGP replacement parts is a fascinating blend of advanced technology, precision engineering, and high-stakes competition. The demand for high-quality, rapidly available parts is immense, driving innovation in manufacturing and logistics. Understanding the complexities of this intricate system provides a deeper appreciation for the incredible feats of engineering and athleticism that define MotoGP.

References

While specific manufacturers and suppliers are often kept confidential due to competitive reasons, general information on materials science and manufacturing techniques used in motorsport can be found through reputable engineering journals and websites. Search terms like “advanced materials in motorsport,” “CNC machining in aerospace and motorsport,” and “additive manufacturing in racing” will yield relevant results.

Call to Action: Want to learn more about the cutting-edge technology behind MotoGP? Subscribe to our newsletter for exclusive insights into the world of motorcycle racing!

FAQ Summary

What materials are commonly used in MotoGP replacement parts?

Common materials include carbon fiber, titanium, magnesium alloys, and high-strength aluminum. The choice of material depends on the specific part and its function, prioritizing strength, weight reduction, and durability.

Are MotoGP replacement parts street legal?

This varies greatly depending on the specific part and local regulations. Some parts may be legal for street use, while others are strictly for track use only. Always check local laws and regulations before installing any replacement parts on a street-legal motorcycle.

How much do MotoGP replacement parts typically cost?

Prices vary dramatically depending on the part, material, and manufacturer. Expect a significant investment, as these parts are often high-end and made with premium materials and advanced manufacturing techniques.